Biphasic liquid dosage forms

Biphasic liquid dosage forms such as suspensions and emulsions, are pharmaceutical preparations that consist of two distinct, immiscible phases. These two phases can be different according to their composition, density, and solubility. biphasic liquids are of two types, such as suspensions and emulsions, consisting two immiscible phases. In this article we will study advantages, disadvantages, classification, formulation, stability, and evaluation of biphasic dosage forms is crucial for their proper development and use.

Suspensions

Suspensions are a type of biphasic liquid dosage form where solid particles are dispersed in a liquid medium. These solid particles are not fully soluble in the liquid but remain suspended throughout the formulation due to continuous agitation or the addition of suspending agents. Suspensions are used for drugs that are insoluble or poorly soluble, and they provide a liquid dosage form for such drugs. They can be administered by various routes including oral, intramuscular, subcutaneous, intranasal, inhaled, topical, ophthalmic, or otic.

Advantages of suspensions

- Ease of Delivery: Suspensions facilitate the delivery of low soluble therapeutic agents.

- Dispersion of Bitter Drugs: Suspensions can mask the bitter or unpleasant taste of drugs.

- Increased Bioavailability: Suspensions can increase the bioavailability of drug dosage.

- Controlled Drug Delivery: Suspensions may be formulated to provide controlled drug delivery.

- Chemical Stability: Certain drugs are chemically unstable in solution but stable when suspended.

- Resistance to Degradation: Suspensions offer resistance to degradation of drugs due to hydrolysis, oxidation or microbial activity.

Disadvantages of suspensions

- Physical Stability: Sedimentation and compaction can cause stability issues.

- Bulky: Suspensions require careful handling and transport.

- Difficult Formulation: Uniform and accurate dose of the therapeutic agent cannot be obtained unless it’s packed in the unit dosage form.

- Less Reliable Dosage: Accuracy of dosage is less reliable than with solution unless the suspension is packed in the unit dosage form.

- Lack of Elegance: Aesthetic pharmaceutical suspension is difficult to formulate.

Preparation of suspension

Suspensions are prepared using two main methods.

Precipitation Method: This involves dissolving water-insoluble drugs in water-miscible organic solvents and then adding the organic phase to distilled water under suitable conditions. There are three types of precipitation methods.

- Organic Solvent Precipitation: Dissolve water-insoluble drugs in water-miscible organic solvents and then add the organic phase to distilled water.

- Precipitation by pH: Change the pH of the medium. This method applies only to those drugs in which solubility is dependent on pH value.

- Double Decomposition: A reaction in which two chemical compounds exchange ions, typically with the precipitation of an insoluble product.

Ingredients used in preparation of suspensions

- Preservatives: Used to prevent growth of microorganisms. Examples include phenol, chlorocresol, and benzalkonium chloride.

- Antioxidants: Used to prevent deterioration of preparations by oxidation. Examples include ascorbic acid, sodium bisulfite, and BHT (Butyl hydroxytoluene).

- Glidant/Anticaking Agent: Anticaking agents are additives used in suspensions to prevent the formation of lumps or “cakes” by absorbing excess moisture or by coating particles to make them water repellent. They ensure that any solid particles in the formulation are kept uniformly distributed within the continuous phase, thereby maintaining the physical stability of the product. Examples silicon dioxide, calcium silicate, and magnesium stearate

- Coloring Agents/Colorant: Enhance the appearance of the pharmaceutical product.

- Flavouring agent and Fragrance: Improve the taste and smell of the pharmaceutical product.

- Sweetener or Sweetening agent: Improve the taste of the pharmaceutical product.

- Surfactant: Used to reduce the interfacial tension between two phases.

- Release-Modifying Agents: Modify the drug release from the dosage form.

Wetting Agents

Wetting agents are additives included in a pharmaceutical suspension to improve the interaction between the solid drug particles and the liquid vehicle. They play a crucial role in dispersing the drug particles uniformly throughout the suspension and preventing them from clumping together or floating to the surface.

- Hydrophobic vs. Hydrophilic: Drug particles can be hydrophobic (water-repelling) or hydrophilic (water-attracting). Hydrophobic particles have a high interfacial tension with water, making it difficult for the liquid to wet their surface. This can lead to aggregation (clumping) and poor dispersion in the suspension.

- Surface Tension Reduction: Wetting agents, typically surfactants, act by reducing the interfacial tension between the solid particles and the liquid vehicle. Surfactants have a dual nature: one end (hydrophilic) loves water, and the other end (lipophilic) attracts to oil or fat.

- Surfactant Action: When a wetting agent is added to the suspension, its molecules adsorb onto the surface of the drug particles. The hydrophilic end interacts with the water molecules, while the lipophilic end interacts with the drug particle’s surface. This reduces the interfacial tension, allowing the liquid to spread more easily over the particle and promote wetting.

Benefits of Wetting Agents:

- Uniform dispersion of drug particles

- Prevents settling and caking

- Improves stability of the suspension

Examples of Wetting Agents:

- Non-ionic surfactants like polysorbates (Tween®)

- Anionic surfactants like sodium lauryl sulphate

Suspending Agents

Suspending agents, also known as thickening agents, are another class of additives used in pharmaceutical suspensions. Their primary function is to increase the viscosity of the liquid vehicle.

- Higher viscosity creates a thicker suspension, hindering the settling of drug particles. The increased resistance to movement slows down the particles’ natural tendency to sink under gravity.

- This ensures the drug remains uniformly suspended throughout the liquid, allowing for accurate dosing when the medication is dispensed.

Types of Suspending Agents:

- Natural: Alginates, tragacanth, acacia

- Semisynthetic: Cellulose derivatives like sodium carboxymethylcellulose, hydroxyethyl cellulose

- Synthetic: Carbopol®, Veegum®

Selection of suspending agent depends on factors like:

- Desired viscosity

- Compatibility with other ingredients

- Organoleptic properties (taste, texture)

- Cost

Dispersion Method: To ease the wetting and dispersion of the solid phase, a vehicle must be formulated in this method. To ensure uniform wetting of hydrophobic solids, the use of surfactant is desirable.

Types of suspensions

Depending on the appearance of suspension they are classified as flocculated and deflocculated suspensions.

Flocculated Suspensions

Flocculated suspensions are those in which particles form loose, open networks known as floccules. These suspensions show rapid sedimentation, resulting in loose sediment. The structure of the aggregates is quite rigid; hence they settle quickly to form a high sediment height and are easily redispersible because the particles constituting individual aggregates are sufficiently far apart from one another to preclude caking.

Deflocculated Suspensions

Deflocculated suspensions are those in which no flocculation has taken place. Hence, there are no floccules/aggregates. Here, single particles act as individual particles. When sedimentation occurs, these single particles settle. In a deflocculated suspension, dispersed particles exist as separated units, resulting in a smooth-looking suspension. Compared with the flocculated suspension, this suspension sediment slowly and attains the lowest possible sediment height. The interparticle interaction in such compact sediments is relatively high because the interparticle distances are small, leading to the undesirable phenomenon of caking, a tightly packed sediment that was almost impossible to resuspend even with vigorous shaking.

Stability problems

Pharmaceutical suspensions can face several stability problems. Here are some of them along with methods to overcome these issues.

- Sedimentation: This occurs when particles settle at the bottom of the container over time. To prevent sedimentation, the suspension can be regularly shaken or stirred. Additionally, using suspending agents or thickeners can enhance stability.

- Chemical Instability: The drug must remain chemically stable over the intended shelf-life of the product.

- Physical Instability: To obtain a suspension that is chemically and physically stable, factors such as the settling/sedimentation rate of the suspended particles, limitations of Stokes’ Law, sedimentation in flocculated and deflocculated systems, controlled flocculation, effects of particle size on suspension stability, crystal growth, and the use of structured vehicles need to be considered.

Methods to overcome stability problems

The specific methods to overcome stability problems can vary depending on the specific characteristics of the pharmaceutical suspension. Methods to overcome these problems includes following.

- Genetic Engineering, Side-Directed Mutagenesis, Fusion Strategies, Solvent Engineering: These techniques can be used to modify the properties of the particles in the suspension.

- Addition of Various Preservatives, Surfactants, and Additives: These can help improve the stability of the suspension.

- Use of Structured Vehicles: An alternative way of inducing stability in suspensions where gravitational forces dominate is to introduce a network structure into the continuous phase to give the system a yield stress.

Applications

Pharmaceutical suspensions offer a versatile dosage form with several key applications like,

- For Difficulty Swallowing: Suspensions are ideal for patients who have trouble swallowing tablets or capsules. The liquid format makes it easier to administer and take the medication.

- Insoluble Drugs: If a drug is poorly soluble in water, formulating it as a suspension allows for even distribution and easier absorption in the body.

- Taste Masking: For medications with a bitter or unpleasant taste, suspensions can be flavored or sweetened to make them more palatable, especially for children.

- Controlled Release: Suspensions can be designed for sustained or controlled release of the medication. The larger particle size or specific additives can slow down the drug’s dissolution and absorption into the body.

- Improved Stability: Certain drugs may degrade in solution but remain stable when suspended. This allows for a liquid dosage form while preserving the drug’s potency.

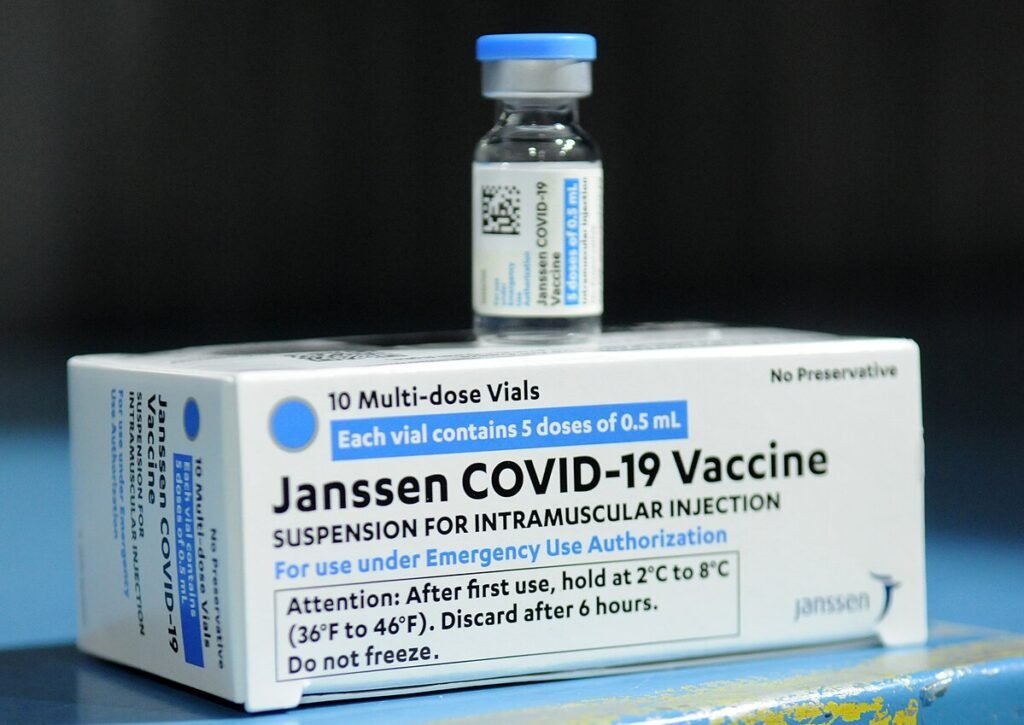

- Topical and Injectable Applications: Suspensions are not limited to oral use. They can be formulated for topical application to the skin or mucous membranes (e.g., calamine lotion) or administered by injection (e.g., some vaccines).

Conclusion

A pharmaceutical suspension is a medication with solid drug particles evenly dispersed in a liquid. To ensure proper dosing, it requires shaking before use. During preparation, finely ground drug powder is mixed with a liquid vehicle, often flavored or sweetened. Wetting agents help the liquid coat the particles and prevent clumping, while suspending agents thicken the liquid to slow down settling. The final product is then packaged in containers for safe and accurate administration.

for practice MCQ on above topic please visit: Practice MCQ For Government Pharmacist Exams » PHARMACAREERS

For more regular updates you can visit our social media accounts,

Instagram: Follow us

Facebook: Follow us

WhatsApp: Join us

Telegram: Join us